Introduction to 3D printers and CAD-CAM Design

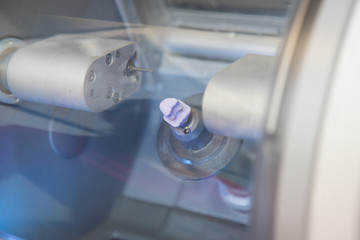

Among the most remarkable innovations is the use of 3D printers and CAD-CAM design (computer-aided design and computer-aided manufacturing) technology. It has transformed the way dental professionals provide care to their patients. Beyond dental crowns, these advancements are reshaping various aspects of dentistry, from dentures to orthodontic devices. In this article, we will explore how 3D printers and CAD-CAM designs are revolutionizing the dental industry.

Dentures

Traditional denture fabrication involved multiple steps and manual labor. With 3D printing, the process has become more efficient and precise. Dentists can now create digital impressions of the patient’s mouth, which are then used to design and 3D print customized dentures. This approach not only reduces production time but also results in dentures that fit comfortably and look more natural. 3D printed dentures are also much stronger and durable.

Occlusal and Night Guards

Patients who suffer from bruxism or require occlusal adjustments benefit from custom-fitted occlusal and night guards. CAD-CAM technology allows for the precise design of these devices, ensuring they fit snugly and provide optimal protection.

Sport Guards

Athletes often rely on sport guards to protect their teeth during physical activities. 3D printing enables the creation of custom sport guards that are comfortable, secure, and offer superior protection compared to generic, over-the-counter options

Temporary Crowns and Bridges

Temporary crowns and bridges are pivotal in dental implant treatments, serving as placeholders until permanent restorations. Traditionally, they were functional but not very durable.

However, with the advent of 3D printing and CAD-CAM technology, temporary crowns and bridges have become remarkably strong and long-lasting. These modern temporaries can endure daily use without chipping or breaking, making them especially suitable for longer treatment plans involving dental implants and their healing time.

In summary, 3D-printed temporary crowns and bridges, renowned for their strength and durability, are excellent choices for patients with extended treatment plans involving dental implants. They offer reliable support and enhance the overall dental implant experience, ushering in a new era for temporary restorations.

Porcelain and Zirconia Crowns

Beyond traditional crowns, 3D printing has expanded the range of materials available. Porcelain and zirconia crowns, crafted with CAD-CAM precision, provide patients with durable, aesthetically pleasing options that blend seamlessly with their natural teeth.

Models and Smile Designs (WAX up)

Accurate models are essential for treatment planning and communication with patients. CAD-CAM technology produces highly detailed models, aiding in the design of smile makeovers (WAX ups) and facilitating patient discussions about their treatment options

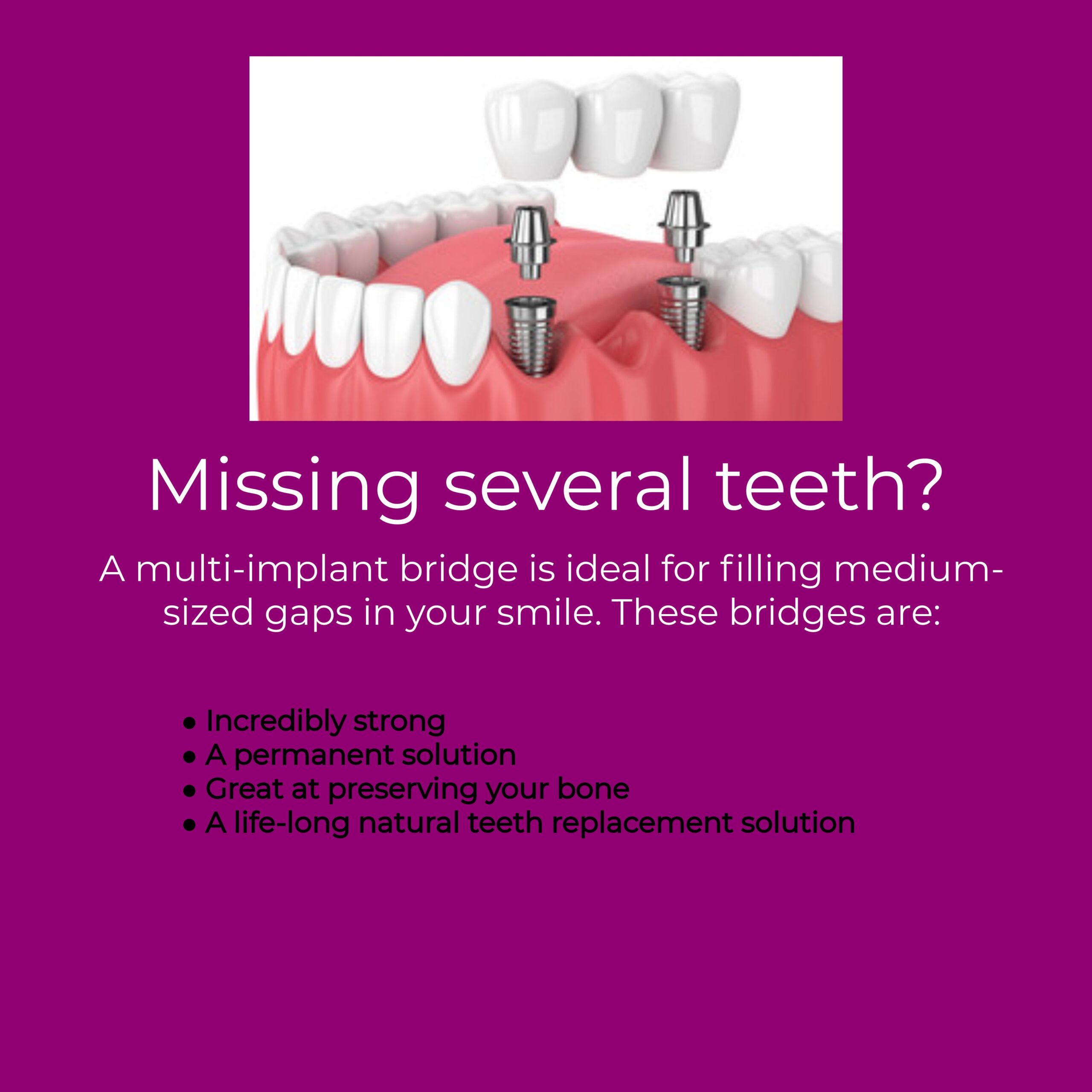

Metal Frames for Dental Bridges and All-on-X Restorations

Precision is paramount when fabricating metal frames for dental bridges and All-on-X restorations. CAD-CAM technology ensures the exact fit of these frames, while 3D printing allows for intricate designs and lightweight yet durable structures.

Conclusion

The integration of 3D printers and CAD-CAM design into dentistry represents a transformative shift in patient care. These technologies enhance precision, reduce production time, and improve the overall patient experience. Dentists at practices like Bright Smile Dental Office are embracing these innovations to offer a wide range of customized dental solutions, from dentures to crowns and beyond. As technology continues to advance, the future of dentistry promises even more efficient, effective, and patient-centered care